Raven Lining Systems

13105 E. 61st Street

Suite A

Broken Arrow, OK 74012

(918) 615-0020

Location: Tulsa, Oklahoma (West 42nd Place South)

Owner: City of Tulsa

Original Contractor: Raven Chemicals

Estimated Project Date: 1990

Age of Project: 25 years

Inspection Date: August 10th 2015

Type of Structure(s):

This study was completed on three manholes. All were 4’ diameter and ranging in height from 5’ to 7’. All three of the manholes are brick structures that were resurfaced with an unknown cementitious resurfacing product. The manholes were then coated with Raven 405 in the early 1990’s.

Condition of Structure(s):

All three structures had previous repairs at some time.

Structure Results:

Structure 1: This was manhole #247. It was a 5.5’ deep manhole with repairs to both the inlet and outlet. There were numerous patches on the coating that appeared to have been small holidays. No active leaks were noticed. This manhole had three 20mm dollies glued and cored to the coating.

The resulting pulls were:

- 280psi (100% substrate failure)

- 198psi (95% substrate failure, 5% adhesive failure)

- 195psi (25% substrate failure, 75% adhesive failure)

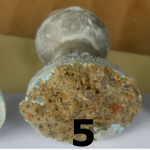

Structure 2: This was manhole #248. It was a 7’ deep manhole with repairs to both the inlet and outlet. One active leak was noted on the south side approximately 1’ above the bench. Unrepaired holidays were noticed, but were not leaking. Three 20mm dollies were glued and cored to the surface of the coating.

The resulting pulls were:

- 500psi (5% substrate failure, 95% adhesive failure)

- 420psi (95% substrate failure, 5% adhesive failure)

- 460psi (90% substrate failure, 10 adhesive failure)

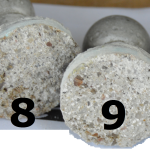

Structure 3: This was manhole #249. It was a 7’ deep manhole with previous repairs to the outlet pipe. There was cracking of the coating around the transition from the concrete manhole to the cast ring. Four 20mm dollies were glued and cored to the surface of the coating.

The resulting pulls were:

- 605 (100% substrate failure)

- 400 (100% substrate failure)

- 380 (100% substrate failure)

- 485 (97% substrate failure, 3% adhesive failure)